在制造业进行供给侧结构性改革的同时,糖果机械行业也面临着产业结构调整的问题。随着科学技术的发展,包装机市场规模越来越大,设备功能也越来越丰富。面对日益增长的市场需求,包装机设备行业也在悄然进行着转型。

产业结构亟待调整。如何提高包装机的竞争力?

“十三五”期间,中央经济工作会议曾明确提出,在适度扩大总需求的同时,着力加强供给侧结构性改革。包装机械行业也面临着产业结构调整的问题。如何提高包装机的竞争力?企业只有在明确当前行业发展趋势和目标的前提下,才能确保整个行业科学可持续健康发展。

近年来,受经济环境和国家相关环保政策影响,我国包装行业增速逐渐放缓。但从行业整体来看,我国包装市场无论高端还是低端产品都有良好的发展空间。在此背景下,我国自动包装机将成为包装行业中 具发展潜力的包装机械。

随着科学技术的发展,包装机市场规模越来越大,设备功能也越来越丰富。另外,消费者对包装的审美观念和实用性都发生了变化,自动包装机也在随着市场需求不断改进和完善。目前,超市、商场、药店的产品包装设计越来越多样化,体现了自动包装机的逐渐多样化。各种包装机,如食品行业使用的真空包装机、颗粒包装机、全自动包装机等,其功能正在逐步完善,并具有电子标签打印功能。有了标签,就可以保证产品来源的安全性和可追溯性,更好地满足消费者的需求。

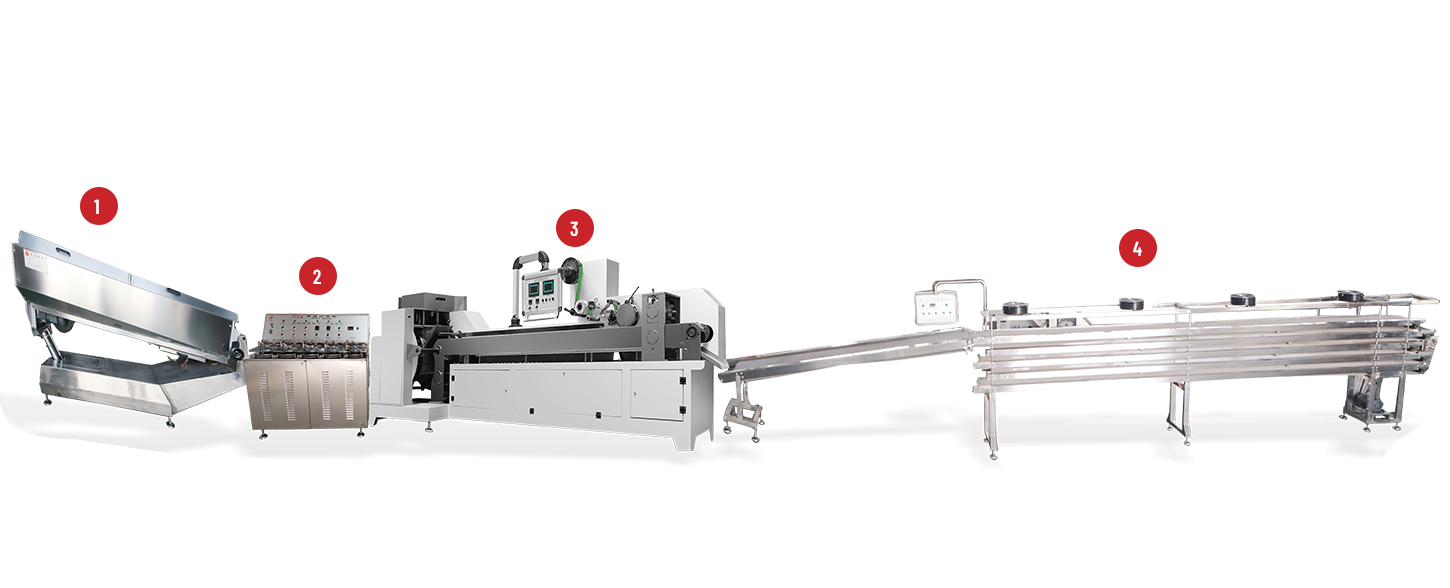

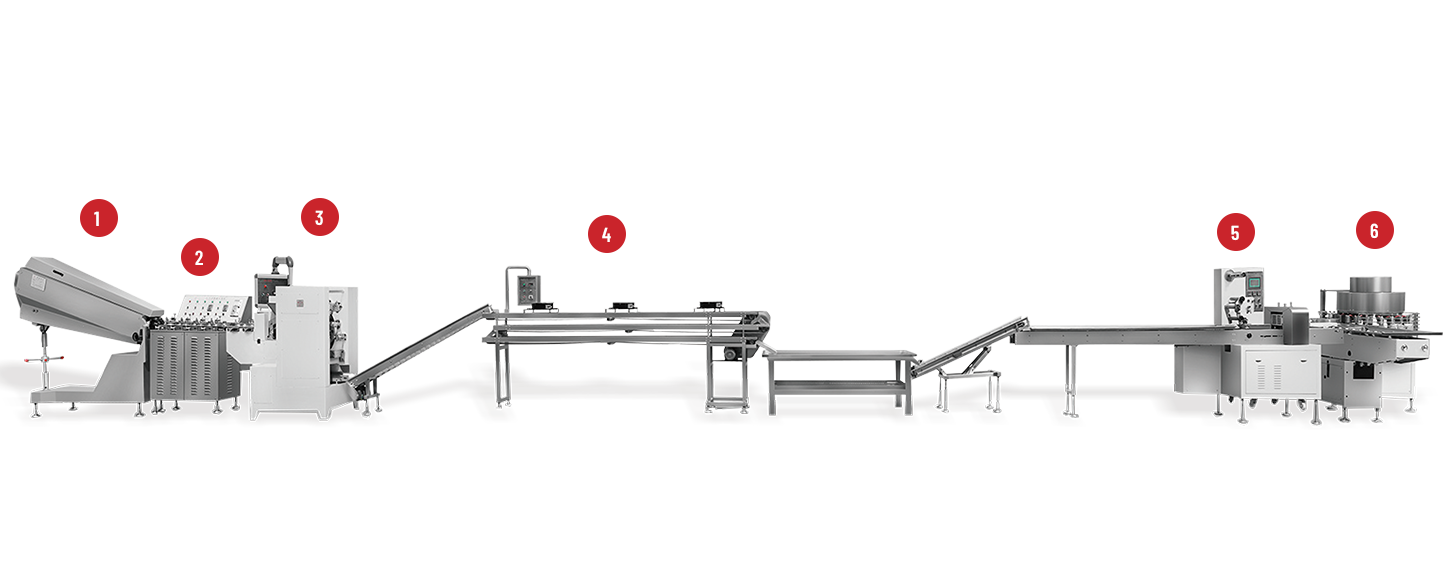

面对日益增长的市场需求,包装机设备行业也在悄然进行着转型。高度自动化、智能化、多功能、高效、低耗的包装设备备受业界青睐。未来的包装机械只有配合工业自动化的趋势,才能推动包装设备行业整体水平的提高。例如,高智能数控系统、编码器和数字控制元件、电力负载控制等新型智能装置在包装机械设备中得到广泛应用,使设备使用者操作更加独立、灵活、正确、高效、兼容。操作期间。

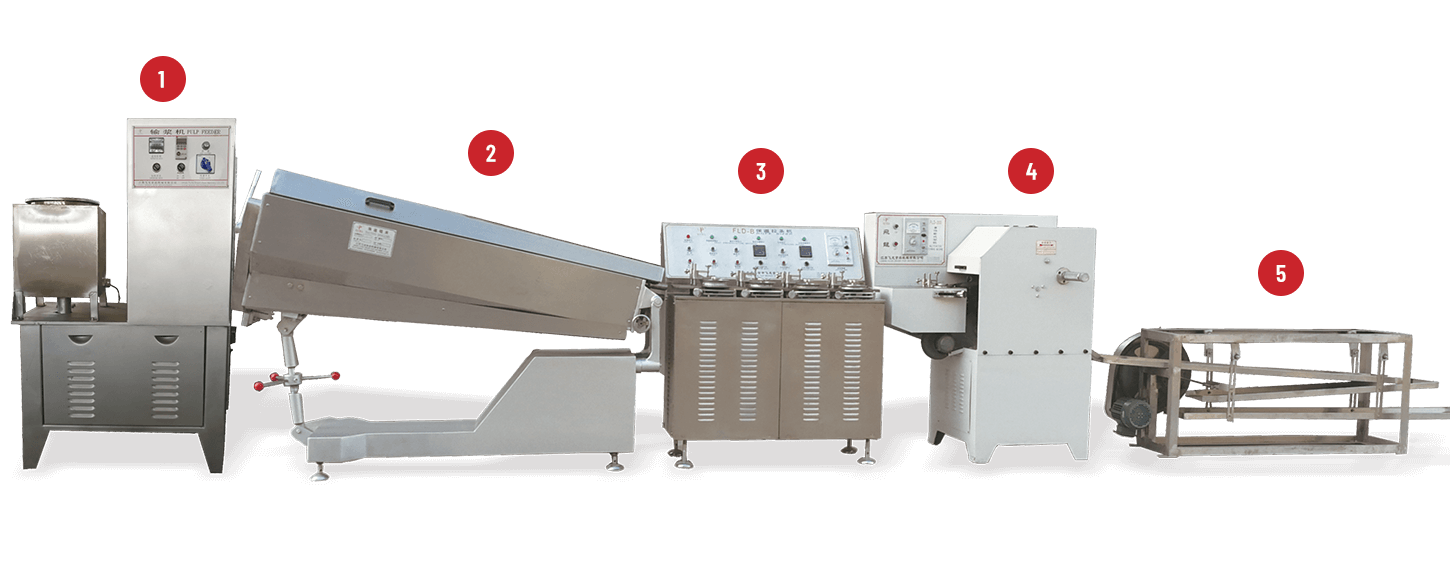

专家介绍,目前,我国米粉加工设备主要涉及两项自动化技术:现场总线技术和传感器技术。现场总线技术可以“解放”传统的包装环节,简化繁琐,具有明显的便利性和灵活性。可以通过系统检索和分析运行数据,了解生产的实际即时情况,监控车间的运行情况,为整条生产线的无人化运行以及传输、检测和控制的无缝连接提供了便利。其他流程;传感器技术广泛应用于食品、医药等包装机械行业,如食品饮料储罐的监控、灌装包装、混合加工、冷却加热、清洗、包装等过程。使用传感器。国家统计局数据显示,2015年,我国包装行业规模以上企业主营业务收入合计11365.48亿元,市场规模上万亿,成为世界包装大国。在包装行业稳步增长的当下,包装设备制造商需要不断加大创新力度,吸收和学习国外先进技术,不断突破,以加快我国自动化包装机企业的发展并逐步提高。我国自动包装机性能不足的现状

选择语言

选择语言

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

0515-8465666

0515-8465666 0515-85566996

0515-85566996 138 1559 9708

138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

首页

首页